SMALL SERIES/PROTOTYPE DIES & JIGS

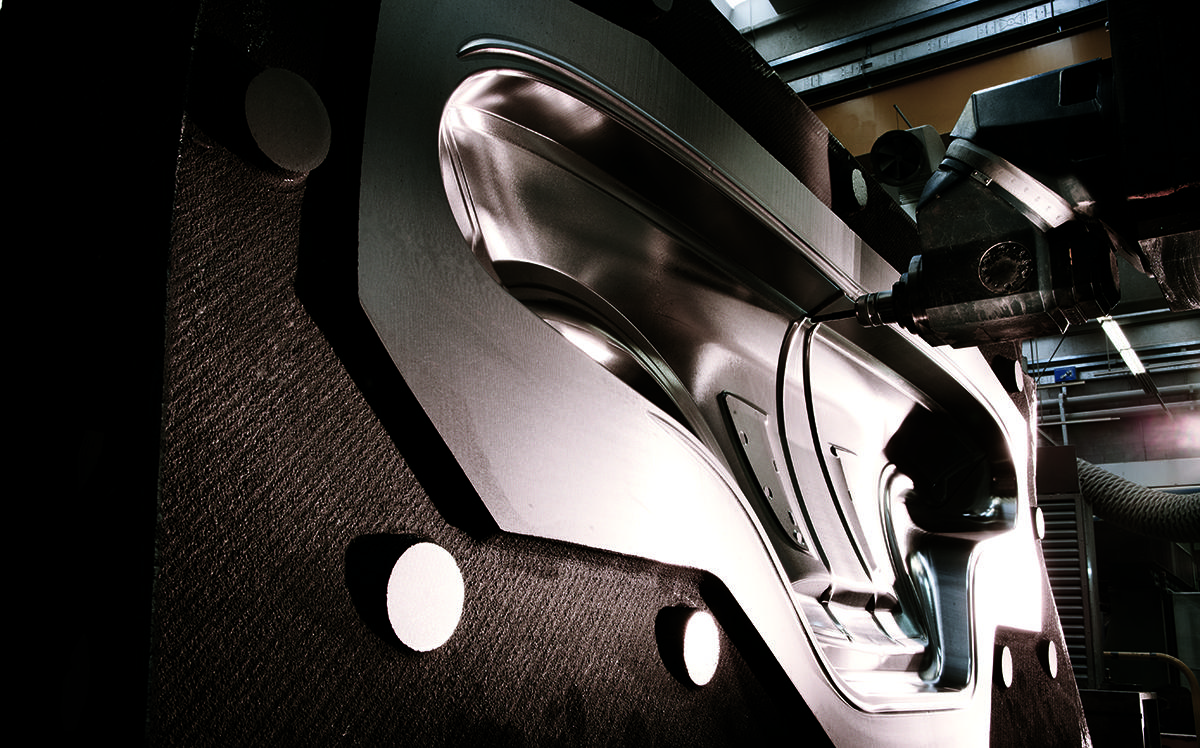

Italdesign workshop develops prototypes and close-to-series dies, as well as tools to build handmade body parts. It can supply any size of mobility vehicle body parts, in steel or aluminum.

Assembling a small series means to overcome a lot of different challenges: special tools to be designed and produced, new building processes, inedited solutions.

This is where creativity comes in handy, together with the most up-to-date technology and machinery; this allows Italdesign to produce up to 12 BIW per week.

Italdesign can count on dedicated tools such as 9 presses, 4 laser cutting robot stations, 9 robots for the production of body parts and subassemblies, 13 measuring and scanning systems for quality control, 2 BIW welding lines equipped with 4 Geo Boxes, 50 spot welding adaptive guns and 15 CO2 MIG/MAG welding stations, 14 numerically controlled milling machines.

In the “try out” area, dies tests are performed for processes validation. Through various measuring centers, a consistent high quality of the product is guaranteed.

Furthermore, the workshop can produce prototype and close-to-series Jigs and Fixtures to weld subassemblies.